On a wild night in January 1953, later known as The Muckle Storm, trees crashed to the ground in their tens of thousands.

Across the north-east, many mobile sawmills were drafted in to process the windblown timber over subsequent years.

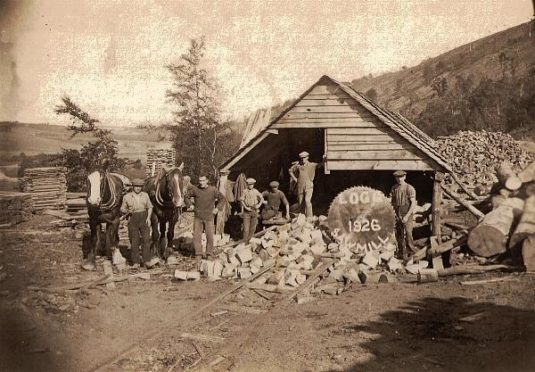

James Jones & Sons had cut wood in mobile sawmills, on Glen Tanar and the other great Deeside estates, for decades.

In the aftermath of the storm, the decision was taken to build the first permanent sawmill in the area, on the banks of the Dee at Burnroot, near Aboyne.

Almost 60 years after it was built in 1962, the Burnroot sawmill is still there by the bend in the river – but it is a very different beast.

First modernised in 1989 with top-range Scandinavian equipment, it underwent a total refurbishment between 2018 and 2020, which has seen a 30% uplift in site production and the upgrade of the biomass boiler to meet the highest environmental standards.

An investment by James Jones & Sons of more than £9 million has created one of the most advanced sawmills in the country, directly supporting the livelihoods of almost 60 people, in increasingly highly-skilled jobs and drawn almost exclusively from the local area.

It’s the biggest private employer in that part of rural Deeside. When added to operations at Mosstodloch in Moray, Kirriemuir in Angus and its I-Joist facility at Forres, James Jones & Sons directly employs almost 250 people in North-East Scotland.

Some regular contractors, who harvest about one-third of the timber for Aboyne and the other mills, are the third generation supplying the company with timber.

James Jones & Sons is a close-knit family business in all respects, as well as the largest privately-owned sawmiller in Scotland.

Company history

Founded by James Jones in 1838, its proud history includes supplying timber for Captain Scott’s legendary Antarctic exploration vessel Discovery.

Tom Bruce-Jones is the fifth generation family chairman, and staff loyalty is immense. A number of Aboyne employees have been with the company for more than 40 years, with many more not far behind.

The mill is ingrained in the fabric of north-east Scotland, with timber taken for decades from the region’s great forests.

Timber from the public forest estate (formerly the Forestry Commission, now Forestry & Land Scotland) initially supplied about two-thirds of the mill’s timber requirement – from Fetteresso Forest near Stonehaven, Buinach in Strathdon and the immense Clashindarroch, south-west of Huntly.

Today about 60% of the timber comes from private estates and forest owners such as Seafield, Candacraig and Glen Tanar as well as forest management companies, including Scottish Woodlands, RTS and Euroforest.

Aberdeenshire and Moray grow some of the very best spruce, and with the most advanced equipment at Aboyne, sawn timber is processed to as high a quality as that from Scandinavia. With 80% of the UK’s wood being imported, this is a valued, essential resource.

Cutting-edge technology

The Burnroot mill is at the cutting-edge (literally) of a vibrant, growing industry.

Aboyne’s work has moved from railway sleepers and pit-props to cutting wood primarily for the construction industry today. Carcassing, or building timber, is about 60% of its output, with 25% produced for pallet manufacture and about 15% for domestic fencing.

Pallet wood has been increasingly vital for moving goods during the pandemic, while greater use of timber in construction is essential to a sustainable future.

Around 85% of new Scottish homes are built with timber frames, and as the construction industry requires longer lengths of timber and more accurate sawing, Burnroot is perfectly placed to deliver this.

The investment in recent years can be likened to restoring a vintage car.

As well as refurbishing the mill’s exterior, modifications under the bonnet involved installing modern technology demanded by 21st Century sawmilling. Many people who don’t know the industry are surprised, and impressed, by the hi-tech nature of modern sawmills and skill levels of the operators and engineers.

Technology is crucial for the accuracy the market demands, and the saw line at Burnroot can transform one large log into 24 smaller pieces in a single pass.

Sawmills are a zero-waste activity with sawn timber going to market, chips and sawdust going to OSB (oriented strand board) and chipboard and bark to horticulture. Any remaining residues are used to fire the new biomass boiler to heat kilns for timber drying.

The wood we cut goes increasingly to Scottish markets, including large building merchants like Jewson and MKM but also smaller merchants all across the north-east. The focus is very much on locally-sourced roundwood timber and for sawn timber and other products to be sold in the region wherever possible

The future looks very positive. Burnroot is part of a thriving regional, and national, forestry and wood processing industry.

The recent investment not only safeguards a large number of direct and indirect jobs in the region and creates significant economic growth but ensures the delivery of our only true naturally renewable resource to customers in the region.

Timber demand is increasing year-on-year as understanding grows that we cannot continue to build with brick, block, concrete and steel if we are to meet our climate change objectives.

- David Leslie is managing director of James Jones & Sons Ltd.