Grandholm Mills once employed thousands of people in Aberdeen — the clicking and whirring of machinery was the soundtrack to many workers’ lives for generations.

The sprawling industrial site on the banks of the Don employed upwards of 3,000 people at any one time in the mid-20th Century.

The company Crombie’s textiles were as important as fishing, granite quarrying and shipbuilding in providing Aberdeen with skilled work.

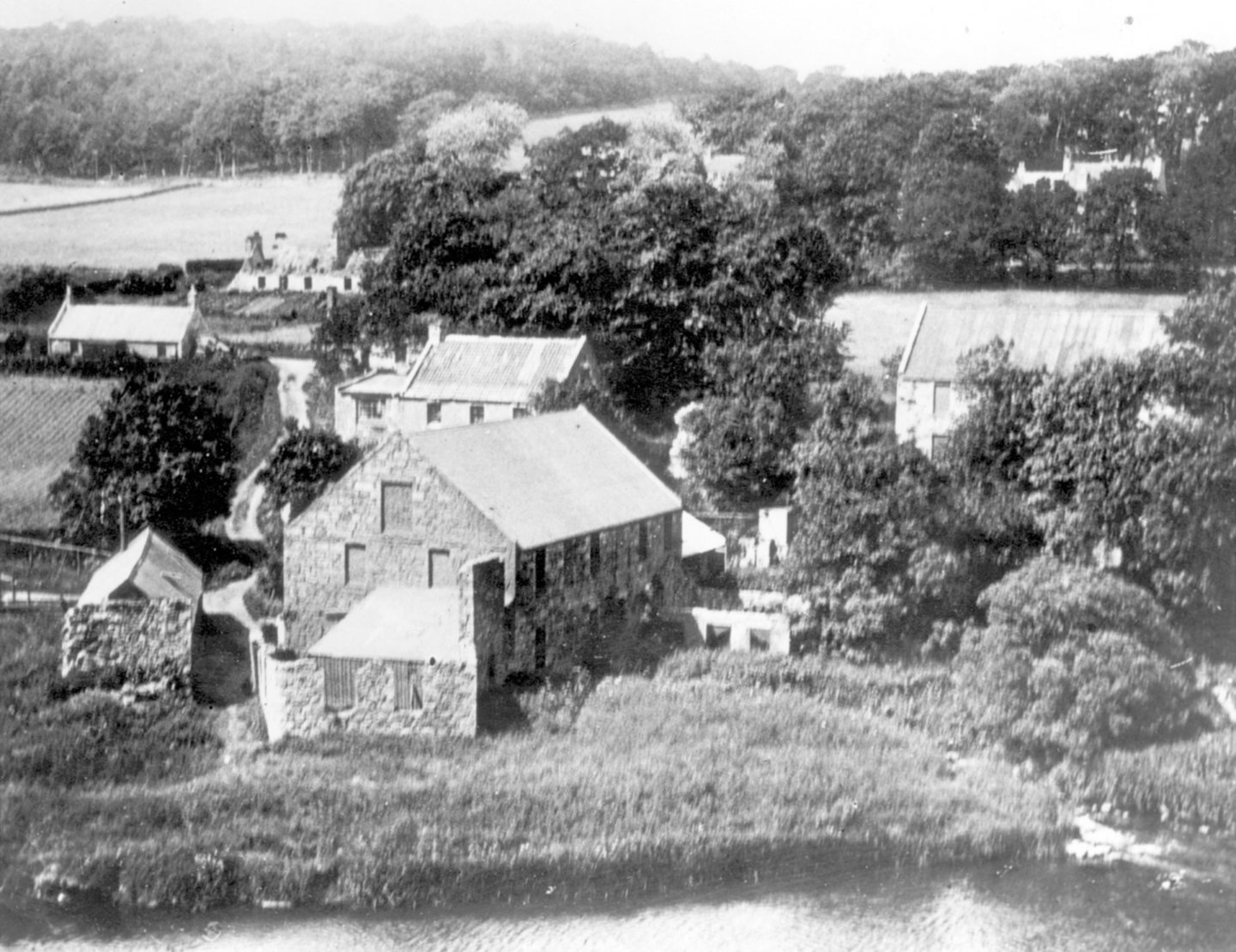

J&J Crombie took over the Grandholm Mills at Donside in 1859 to meet manufacturers’ demand for Aberdeen’s legendary Crombie cloth.

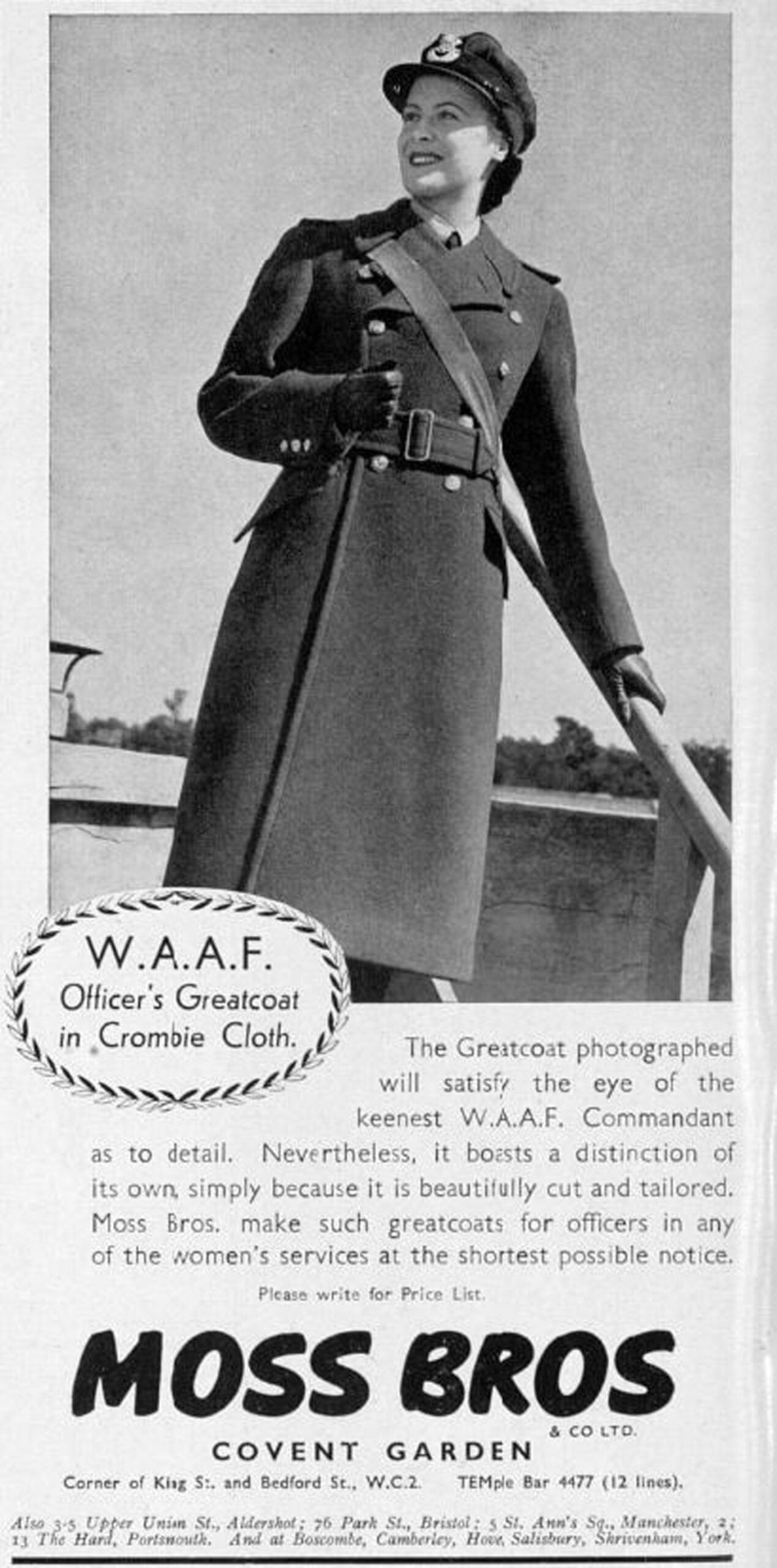

The woollen fabric was then made into the world-famous Crombie coat, which clothed soldiers during both wars, and became a luxury item.

One incredible statistic from the archives reads: “In just one year, Grandholm Mills used cashmere from 100,000 goats, yarn that would have stretched to the moon and back – eight times.

“Piled up, the wool would have been higher than Mount Everest.”

The process provided employment for generations of Aberdonians.

Quality cloth was manufactured at Grandholm Mills

The raw fleeces came in bales from South America, Australia, New Zealand and the Highlands.

The mountains of wool were then checked and processed by hand.

A skill gained only through great experience, the wool sorter could feel the quality as well as see it.

The wool was carefully washed to remove natural grease so that dye would take to the fibre.

It was washed twice in soapy water followed by two gentle rinses.

Clean wool was transported to the dyers’ laboratory where it was coloured, then dried.

Once dry, it would be taken to the blenders where staff would hand-pluck different colours of wool to make the required shade.

Blended wool was then blown into the carding department, where rollers with fine teeth would comb the fibres.

The carding process was completed five times to ensure the utmost quality before wool was loaded onto bobbins for spinning.

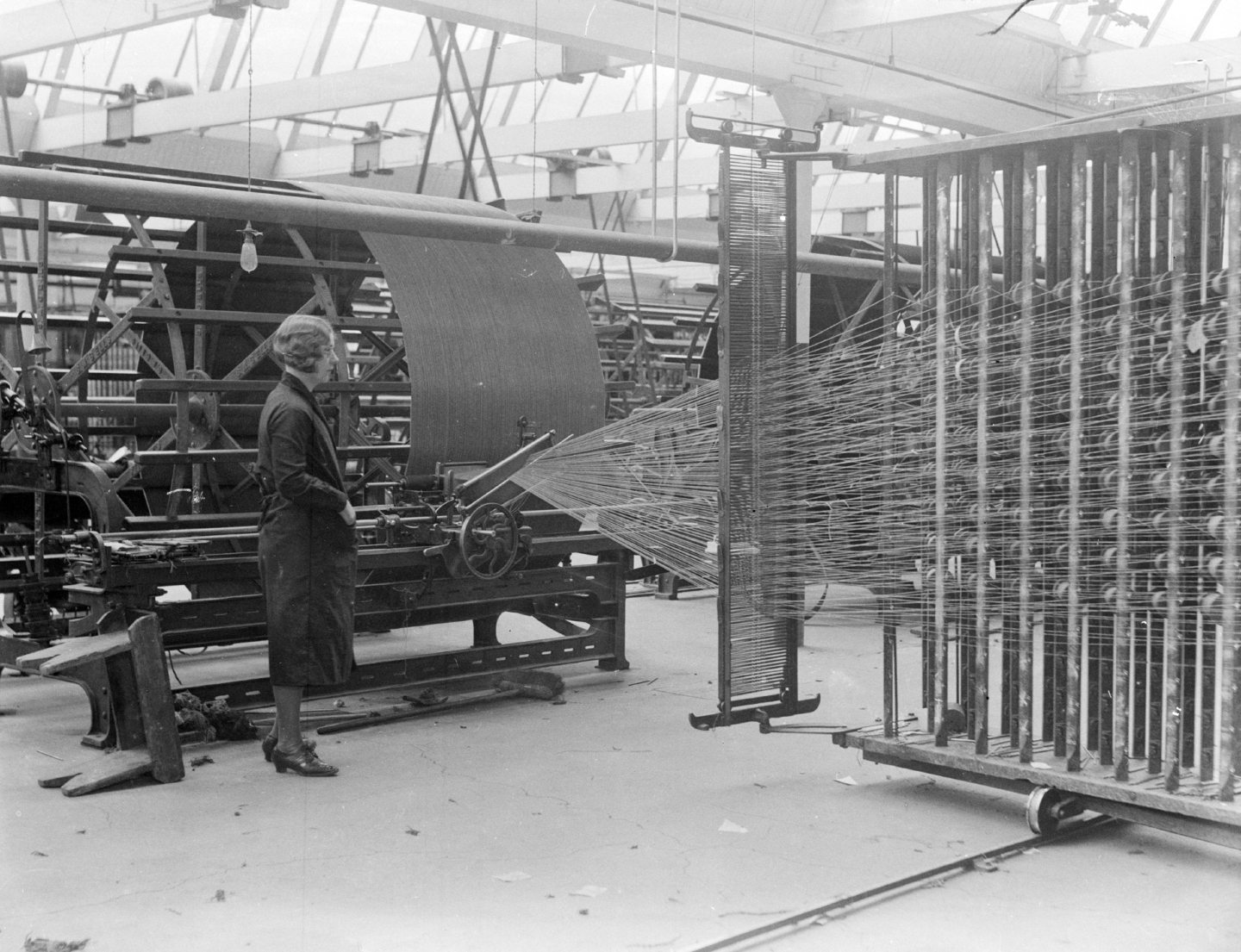

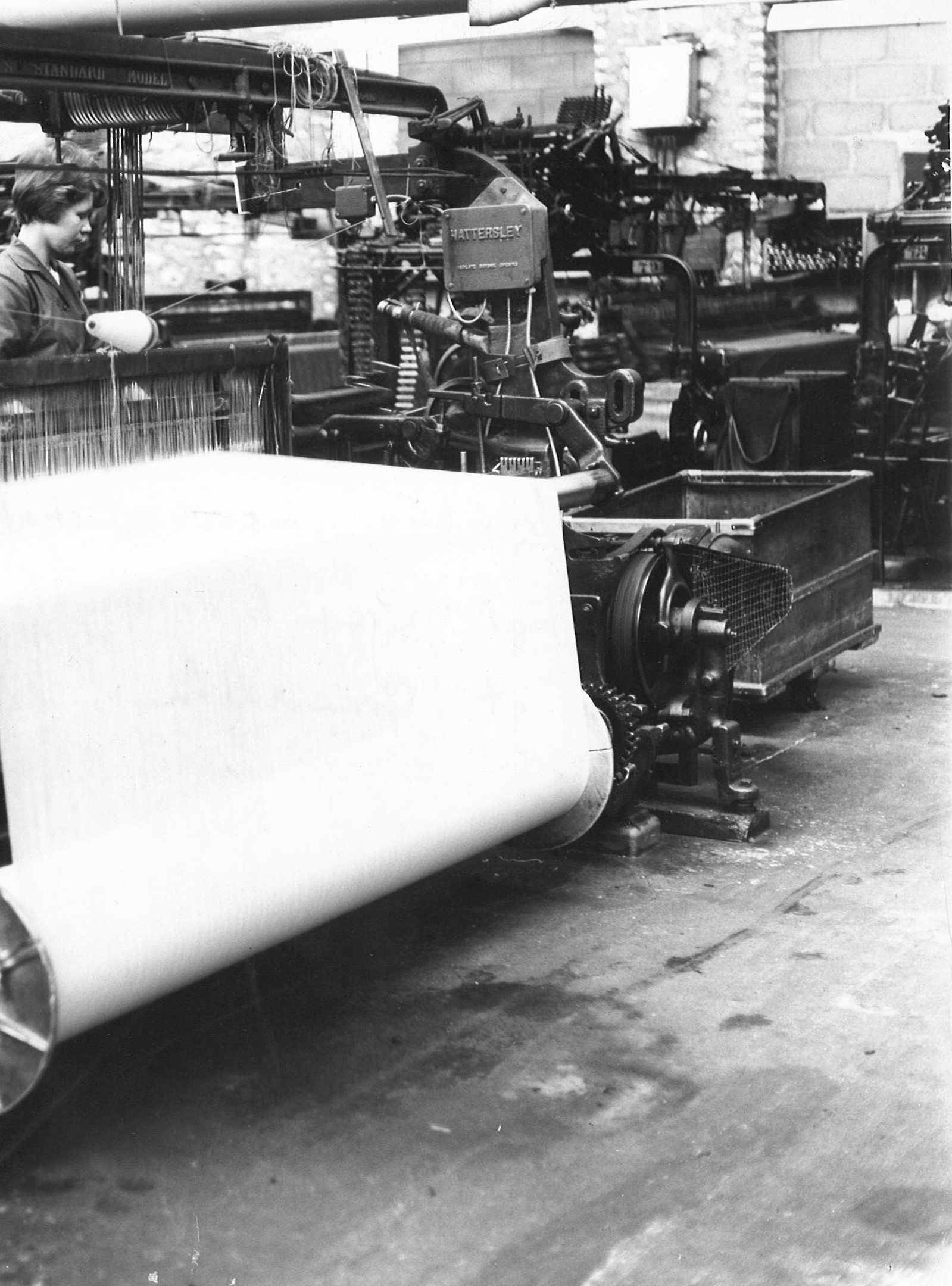

Next was the warping, when yarn would be laid precisely on rollers ahead of drawing and weaving.

Threads were drawn through a reed and onto looms for weaving.

Every step in the complicated manufacturing process was overseen by skilled workers.

Working for Crombie was more than a job – it was a way of life

Each day, hundreds of employees dutifully walked down the 66 steps of Jacob’s Ladder and crossed the bridge over the Don from their homes in Tillydrone and Woodside.

Many Aberdonians started their working careers behind the heavy wooden gates of Grandholm – and many never left.

It was often a job for life; children and grandchildren would follow in the footsteps of their forebears in taking up employment at the world-leading works.

But Crombie wasn’t just a job, it was a way of life.

One of the arguments against diversifying the Aberdeen site when the closure was announced in 1991 was the myriad of different buildings on the site.

But these buildings were likened to a barracks by many who worked there, behind which there was a close-knit workforce of friends and comrades.

Grandholm Works was like a village in itself, a community, not just a wage.

Mill manager Stanley Milton spent his whole 50-year career at Grandholm Works.

Upon his retirement in 1989, he said it would be impossible to “remain unattached”.

He added: “There’s a lot of Crombie in me, and a lot of me in Crombie as well.”

Tides turned against textile industry

Even into the 1980s, Crombie had survived economic turbulence and enjoyed a boom.

When Prime Minister Margaret Thatcher told companies to export, Crombie established a strong foothold in the Soviet Union.

The Cold War and international relations were yet to thaw, but Crombie’s coats transcended the Iron Curtain.

However, the tides turned suddenly for Crombie in 1991 – ironically the year the Cold War came to an end.

Now Aberdeen was being left out in the cold.

The Soviet contract was lost, another was left unpaid, and demand for cloth dropped by 80% in 18 months.

Crombie’s parent company Illingworth Morris announced it would be moving production from Grandholm to Langholm in Dumfriesshire.

They argued the mills were built and designed for a bygone era.

Aberdeen’s heritage lost with Grandholm Mills

It wasn’t just the loss of jobs – it would signify the loss of part of Aberdeen’s heritage.

The weavers were like fisherfolk; they lived where they worked, they shared a lifestyle, and shared a forgotten language of words and skills.

A spokesman at the time said: “At least Crombie, a Scottish company, will be staying in Scotland.”

But that was little comfort to the remaining employees in the mill’s scarfing and finishing department.

The unions fought tooth and nail to save Grandholm, but said they were “denied a national meeting about the closure” and told it was “a local issue”.

As it seems is often the case when industrial jobs are lost in Aberdeen.

Sheila Irvine and her husband Dennis were one of the few remaining residents of tied cottages on the mill site.

A works engineer, her husband had worked at Crombie for 40 years before being laid off in 1989.

She said: “Textiles have always been up and down, but Crombie’s always managed to weather storms.”

While tenants were allowed to remain on site, the way of life and mill traditions were gone.

The Press and Journal said at the time it was “one storm Crombie has failed to weather, – and the loss is Aberdeen’s”.

Gallery: Life at Grandholm Mills in 20 pictures

If you enjoyed this, you might like: