Even on a dreich autumn night after the clocks have gone back, the new Uile-bheist brewery and distillery in Inverness is a welcome sight.

Its copper stills and copper-clad mash tuns gleam in the floodlights.

Uile-bheist is a rare beast – those mash tuns not only produce the “wort” or sugary water needed to make beer but also the wort that eventually becomes whisky too.

The early steps in those two processes are almost identical.

In a horrendously over-simplified way, the secret to producing Scotch is to make a strong beer, then boil it in two big kettles, collect the vapour or “spirit”, and pop it into oak barrels for at least three years.

Uile-bheist and BrewDog ahead of the pack for brewing AND distilling

Jon and Victoria Erasmus unveiled plans for Uile-bheist, next to their Glen Mhor Hotel, last year. They opened its doors to the public and started production earlier this year.

Their brewery and distillery, or “brewstillery”, joins a slowly growing number in the UK.

BrewDog created the LoneWolf distillery – see what they did there? – inside its giant brewery in Ellon, Aberdeenshire, in 2015.

It boasts an impressive arrangement of pot and column stills capable of producing spirits that range from gin and vodka through to rum and whisky.

Steven Kersley, managing director of BrewDog’s distilling arm, described it as “a whisky distillery with a gin problem”.

Sales of its gins and vodkas soared during lockdown, but next year will mark a renewed focus on whisky.

The distillery moved into its own building last year, having outgrown its corner of the brewery’s warehouse.

BrewDog co-founder Martin Dickie always wanted to make whisky and brought Mr Kersley on board in 2014 to help launch the project, which focuses on experimentation, including with a wide variety of yeasts.

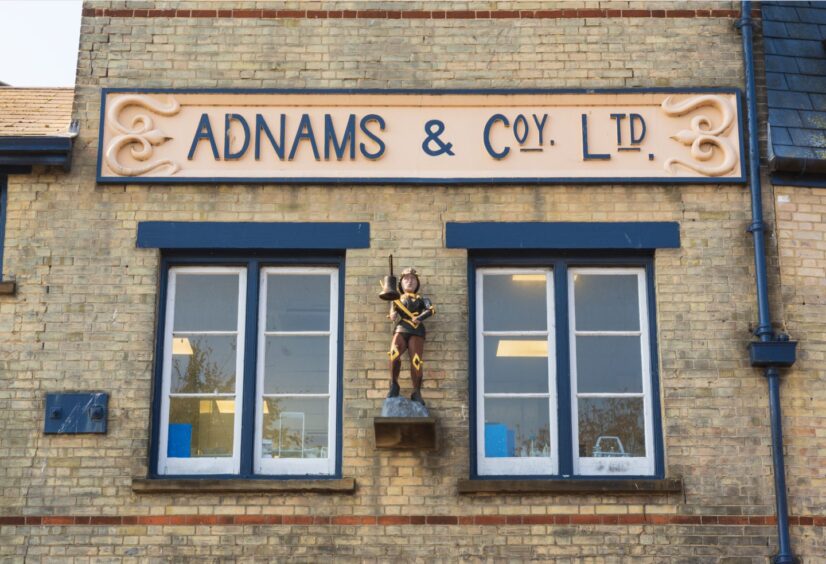

South of the border, Adnams in Southwold, Suffolk, became the first brewery in the UK to install distilling equipment in 2010. Its Copper House brand features gin, vodka and whisky.

Could this trickle of “brewstilleries” soon accelerate into a flood?

Britain’s craft brewing sector is under pressure from the triple blows of Brexit, Covid and inflation.

The Society of Independent Brewers’ latest annual report revealed its members’ output last year was still 11% behind 2019.

Figures from accountancy firm Mazars over the summer showed 45 small brewers were liquidated during the year to March 31 2023, prompting headlines proclaiming the “end of the craft beer boom”.

According to trade body Scotland Food & Drink (SFD), wider social trends are also making brewers consider diversification.

Beer and gin markets ‘contracting’

Andrew Niven, strategic market intelligence manager for SFD’s “knowledge bank” service, said: “Over time, the beer market is contracting – people are drinking less.

“And the gin market is contracting – people are moving to ready-to-drink cocktails.

“Brewers will need to think carefully about what they’re producing if the trend is to continue.”

One man who’s been there, done it and got the t-shirt is Paul Miller, who founded the Eden Mill distillery and brewery on the site of a former paper mill in Guardbridge, near St Andrews, in 2012.

Mr Miller always aimed to make whisky but he knew St Andrews University, which owns the site, planned to redevelop the old mill.

Rather than wait five or six years to build the distillery, he began brewing beer, knowing a craft brewery would be easier to dismantle and move.

Whisky started flowing through stills just two years after start-up at Eden Mill

He soon realised he could add distilling equipment to his existing kit and the first whisky flowed through the stills in 2014.

Mr Miller said: “For a relatively modest sum of money – around £1 million – we could convert the site to produce small batches of whisky, as well as gin, which brought in cash and helped the business to reach profitability at an earlier stage.”

Brewing at Eden Mill ended in 2018 when the university began redevelopment, with gin production shifting to another part of the site.

The company acquired Eden Brewery in Penrith, Cumbria, so it could keep producing its beers, with its whisky distillery at Guardbridge now likely to open next year.

Mr Miller sold Eden Mill to Edinburgh-based private equity firm Inverleith last year and stood down as a director this year, while retaining a minority stake in the business.

He’s now sharing his knowledge and experience to help grow other drink brands, including Panther Milk, a “vegan version of Bailey’s Irish cream”, which is due to relaunch with fresh packaging in January. A pre-mixed cocktail will follow in spring.

Safety regulations are naturally tighter when you make spirits.”

Paul Miller, founder, Eden Mill distillery and brewery

“Lots of brewers were curious when we installed the distilling equipment,” Mr Miller said, adding: “I think the price tag put some people off.

“Safety regulations are naturally tighter when you make spirits.

“I still think it’s an interesting model and one that has lots of merit.

“We’re now reaching a time when consumers are savvier. If you’re claiming to be authentic and produce small-batch products, you have to be able to demonstrate it.

“Producing beer, whisky and gin meant we appealed to a wide range of visitors – they all loved looking under the bonnet to see how we worked.”

Idea catching on overseas too

Brewers overseas are starting to explore distilling, including in the US, where SFD pointed out that complicated liquor laws in some states mean breweries cannot sell cocktails in their taprooms or on-site bars unless they make the spirits themselves.

Briggs of Burton, the brewing and distilling equipment-maker that traces its roots back to 1732, has installed “brewstillery” equipment for Spoetzl in Texas and Coopers in Australia.

Coopers unveiled plans last year to build a micro-brewery, whisky distillery and visitors’ centre at its Adelaide home, while Spoetzl launched its craft gin, vodka and unaged corn whiskey earlier this year.

Spoetzl Brewery, located in Shiner, Texas, and known for brewing Shiner Bock, opened its new onsite distillery, the K. Spoetzl Distilling Company, that will sell Vodka, Gin and Moonshine, also known as "Shiner Shine." https://t.co/d89SbFZyZy

— Houston Chronicle (@HoustonChron) May 10, 2023

“Both have strong brands and distribution networks for their beers,” said Scott Davies, head of marketing at Briggs, which opened an office in Forres, Moray. earlier this year.

Mr Davies added: “For Spoetzl it’s product diversification, while for Coopers I think there’s an element of legacy, laying something down for the next generation in the family-owned business.”

BrewDog has also had brewers visiting from countries, including Belgium and the Netherlands, to study its distillery.

Mr Davies thinks simply buying neutral grain spirit and then redistilling it with botanicals in a pot still to make gin or refining it in a column still to make vodka will appeal to some breweries.

But others will opt for the more complex and expensive option of distilling their wort to make whisky, he said.

However, what to make is only one consideration.

Distillation by-product challenge

Mr Davies reeled off by-products that would-be distillers also need to think of, including wastewater, leftover grain or “draff”, and the liquid remnants or “spent lees”.

“Most people forget that only 10% of the output from a whisky distillery is spirit,” he explained, adding: “You’ve got to deal with the other 90% too.”

Conversation