As mentioned last week, up until recently I’d never given a second thought as to what goes into making a newspaper.

Each day, reporters have been out in the field, photographers taken their photos, interviews done, columnists and feature writers filed their pieces. It’s all scanned by numerous eyes, edited and laid out, and finally sent to be printed.

It may now be late at night and most of us are fast asleep, but it’s far from over when it comes to your daily paper. In fact, it’s just the beginning.

Discovery Print, owned by DC Thomson, who also own the P&J, is based in Dundee. David Dalziel, the P&J’s features editor, had arranged for me to have a guided tour of this state-of-the-art facility.

On arrival, I was met by production manager Craig Bertie. He knew it was my first visit to such a place.

“I presume you’ve got a printer at home George, ink cartridges also?” he asked.

“Yeah, of course.”

“Well, for a minute just think about that desktop printer and tiny ink cartridge, then wait till you see inside here. This is going to blow your mind.”

Deep in the bowels of this huge building, I was shown the gigantic rolls of paper and was gobsmacked when Craig told me one roll if laid out would be 14 miles long. And each roll can be printed off in 30 minutes.

“We go through this entire warehouse of paper in seven to 10 days,” he told me.

The ink cartridges were staggering in size. The colour tanks each contain 10 tonnes of ink, and the black ones 50 tonnes. They go through a mix of up to six tonnes per week.

I’ll never look at my printer cartridges at home in the same light again.

We entered the main hub of the building and I was shown round a computerised area where the templates, for want of a better word, are produced. Through glass walls, I spied the huge printing presses.

Craig took me in there and explained the workings of it all. I have to admit, a lot of it went right over my head. It was so much to take in. I’d just stepped into a high-tech Aladdin’s cave of printing. It was like being inside that TV programme, Inside the Factory, where we get to see what goes into making our everyday products.

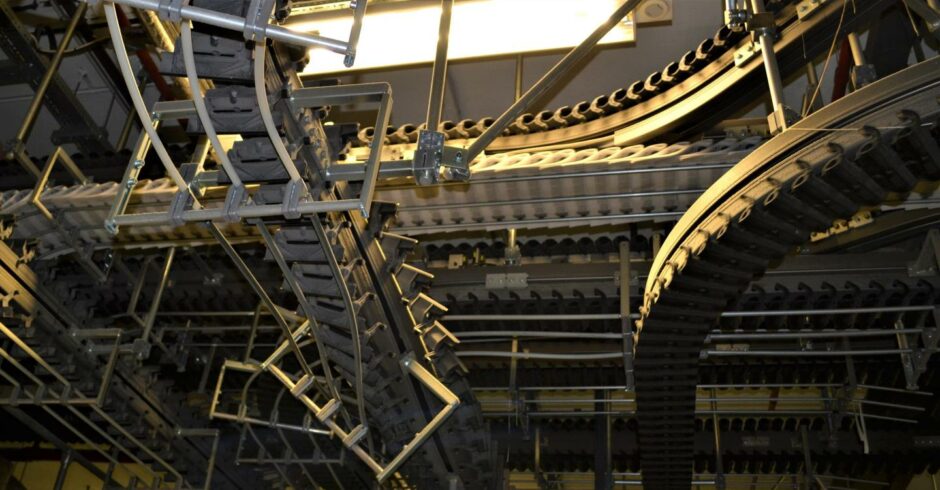

In the next area, gigantic machines lined the walls, while conveyor-belt type mechanisms like a rollercoaster whirred all around and overhead. Finally, I was seeing newspapers being printed.

I felt proud that my column is part, albeit a tiny part, of such a huge, professional, slick operation.

“This can’t have come cheap,” I said.

Craig answered: “In 2012, we installed at the cost of £27 million this Goss CPS press. It was and still is the most modern newspaper plant in the UK.”

As well as all the high-tech wonders, there are real people here of course. Men and women quietly going about their business, all focused on one main aim – to get our newspapers printed to the highest standard and ready to go, on time.

Craig was right, the tour did blow my mind.

Impressively, it’s not only DC Thomson’s own papers like the P&J, Evening Express, Dundee Courier, Sunday Post and such like that print here, it even prints the competition. Titles such as the Scotsman, Daily Mail and others are all printed here.

These days, as you all know, newspapers have numerous magazines and supplements each week. These of course also need printed, which in itself is a huge operation.

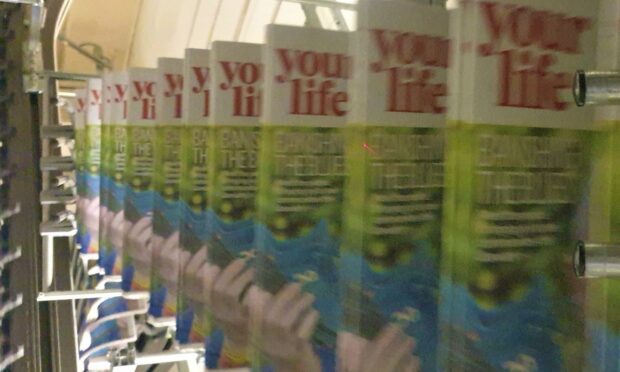

Regarding our very own Your Life magazine, Craig told me: “Take the YL magazine. Once it is printed, it then has to be trimmed and prepared for inserting on Friday night/Saturday morning, a process which takes around six hours.”

Ever wondered how all these Your Life mags get inside every single copy of the P&J? No, neither had I. If you’re thinking some poor guy in the wee small hours, or a newspaper boy or girl in the dark in the back of a small local shop has to hastily physically shove each one in, you’d be way off the mark. Time-wise, not possible.

As if reading my thoughts, Craig confirmed: “YL is printed, trimmed and then inserted all by machine, without any human hand ever touching a copy.”

I viewed the machine that does just that. Fascinating to watch.

“When’s your busiest time Craig?” I asked.

“We print almost 24 hours to get everything away on time; five daily regional titles and four national newspapers every night and we have 60 weekly titles each week. Each week we print around 13 million copies, manufacture 15,000 printing plates, use 300 tonnes of paper and go through 800 pallets per week.

“Our busiest night is Friday with the largest paginations and most titles being inserted with a weekend magazine. And we recycle everything, every scrap of paper, reel wrappers, aluminium plates, carboard, even the food waste from our canteen is recycled.”

“With such a huge operation, near 24/7, lockdown must have been a real headache,” I said.

“Publishing was deemed as essential work so we were allowed to stay open. That said, the first few months were the most challenging. We had 25% of our staff off ill or shielding. Numerous additional safety measures were put into place to reassure remaining staff it was a safe working environment,” said Craig.

Of course, the process of producing your paper doesn’t end with printing, for it’s then got to be physically taken to you.

I interviewed Neil Mackland, head of newspaper sales and marketing, about the delivery process. Regarding lockdowns, he answered with pride: “We never missed a single day in getting the P&J out during lockdown.”

“Once we’re all printed, loaded and ready to go, there’s two big drops. One to Inverness leaves Dundee around midnight, the other to Aberdeen leaves around 2am. From there, in the wee small hours, Menzies vans and other individual contractors then divide up the stacks of papers and deliver them directly to local shops and such like.

“We then have a supply of papers that are taken to Aberdeen airport. They go on a postal flight and are flown to Shetland, to a wholesaler there, then distributed to all outlets.”

Much to my surprise, Neil also told me that the P&J is also flown by helicopter from Aberdeen to offshore oil rigs in the North Sea. He then went on to add: “For getting the P&J to Orkney, the papers are first driven to Inverness, then on to Scrabster, put on a ferry; once in Orkney, they are again distributed to local retailers. Even as far as Orkney, they are usually there by 9.30am.

“As for Stornoway, the papers get sent to Glasgow airport, and are flown on from there.”

But of course, it doesn’t even end there. Many of you go to a specific shop to pick up your paper, while others get it delivered through the letterbox.

We have a boy/girl who delivers our P&J. I’ve never given it a second thought really.

Neil explained that while some local shops employ their own boys/girls, the P&J also directly employs many others. I was astonished when he told me: “We employ 1,000 boys and girls to delivery our papers. They really are absolutely vital in our process.”

“The extra effort that our boys and girls put in during lockdowns in order to get our papers out each and every day, did not gone unnoticed. Our home delivery team scooped the Special 2020 Award at the UK Regional Press Awards.”

Press and Journal editor-in-chief, Frank O’Donnell, said: “Not only did these youngsters keep delivering, they offered to help those who couldn’t leave their homes by bringing vital supplies and running errands. I am proud to know them.”

Thanks to David Dalziel, Struan Nimmo, Neil Mackland and Craig Bertie for their time in making this column possible.

No one likes to pay more for anything. And no company enjoys putting up prices either. But regarding the recent 10p increase of the paper, it’s become apparent to me that this was not a decision made lightly for making a quick buck. Craig told me that paper costs have risen a colossal 70% during the last year. He’s also worried about the rapidly rising costs of energy prices.

Maybe you’re sitting at your kitchen table right now reading this column, or in the lounge, or maybe you’re lucky enough to have someone bring you a copy upstairs and you’re reading this in bed with a brew. Or maybe you’re on an oil rig and have just come off night shift?

Get in touch and let me know where you read your P&J.

Enjoy and have a good weekend

George